Ceramic Linings

- Home

- Products

- Wear Linings

- Ceramic Liners

- Ceramic Linings

Ceramic Linings – Alumina( AL2O3) 92-95% – ZTA, Silicon Carbide with backing in materials to compliment the application- rubber or steel backed – fixings to suit

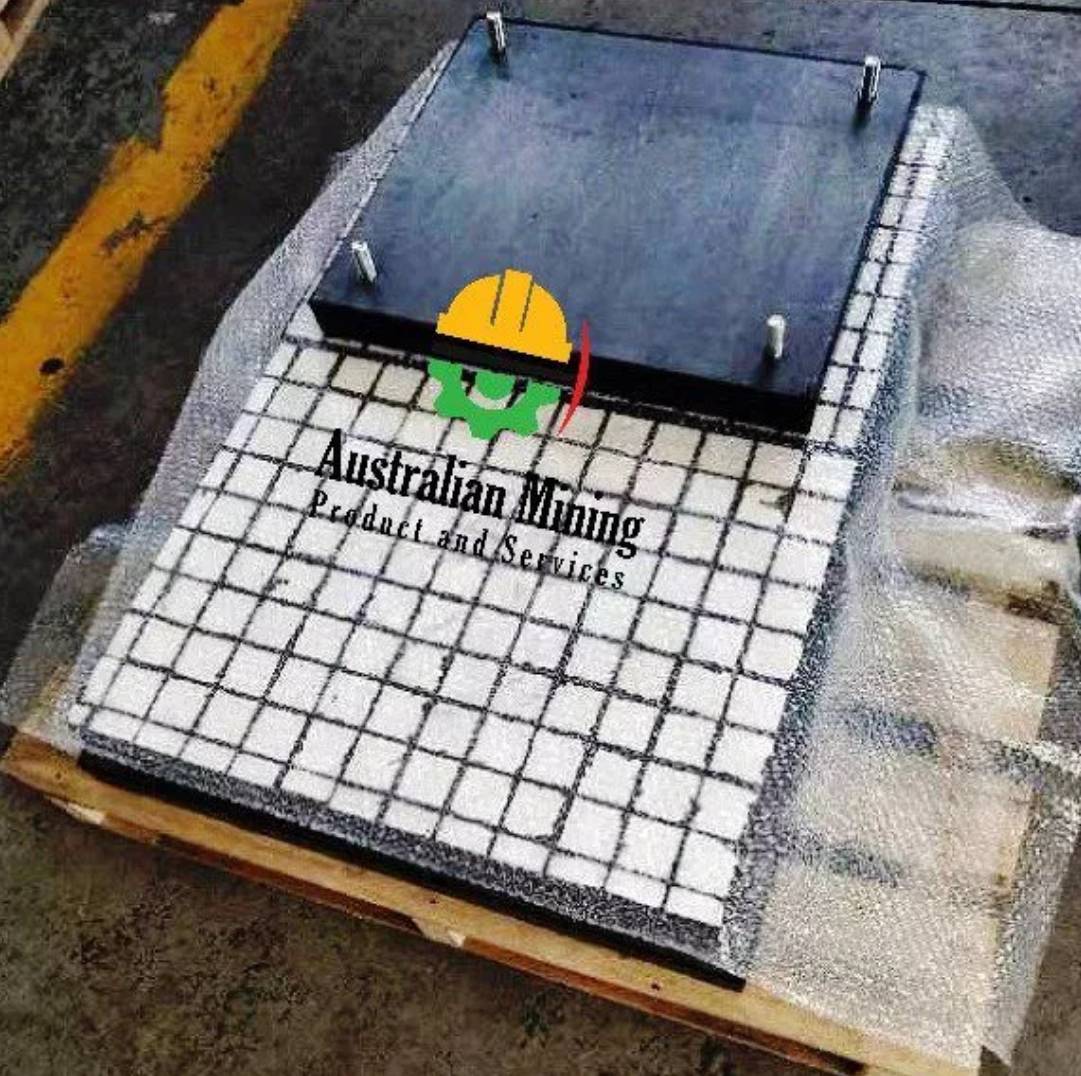

Rubber Backed Ceramic faced liners ( Alumina, ZTA etc ) 6-112 mm thick overall

We have stock or a wide range of ceramic faced wear liners

Specials and may require either an extended lead time or a minimum order quantity

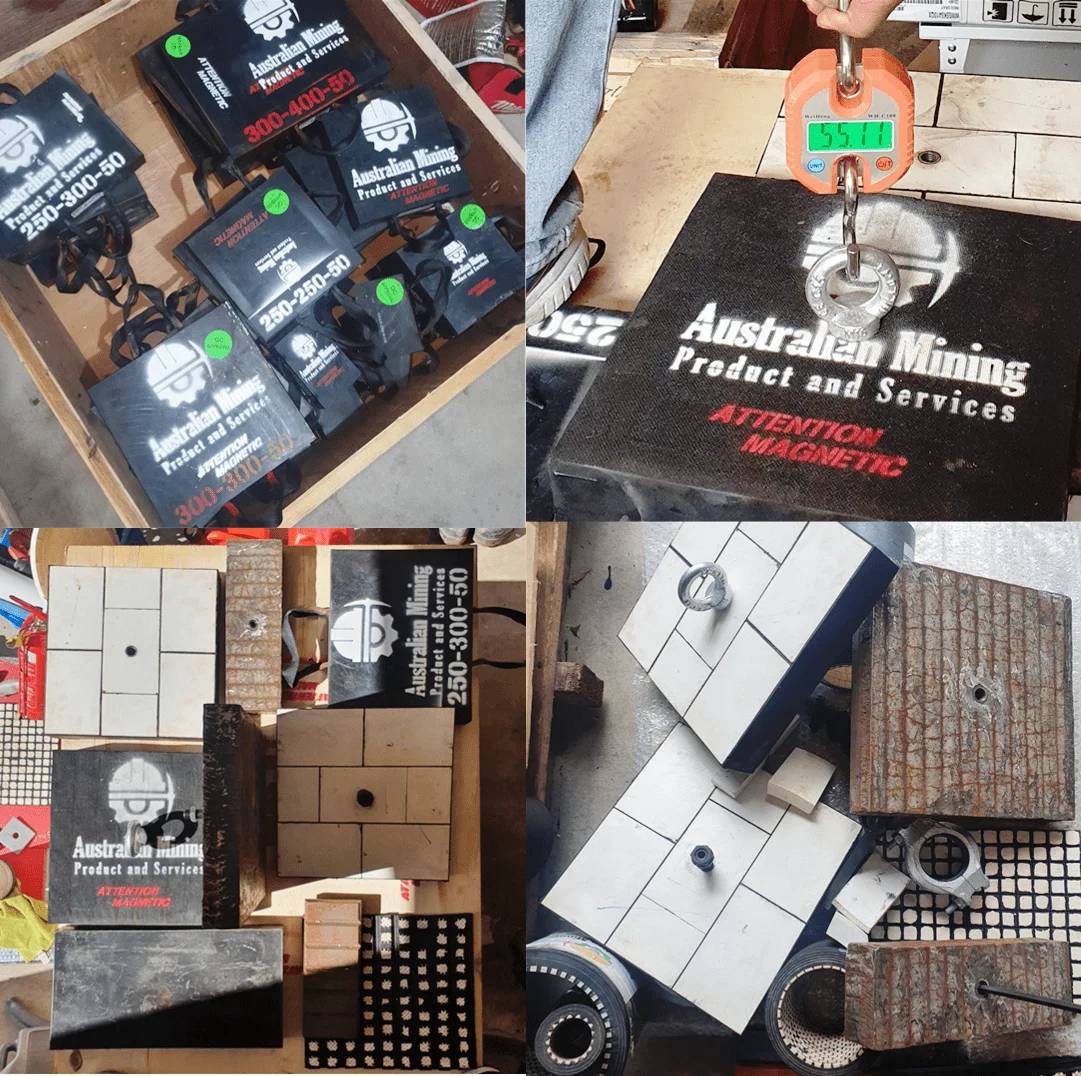

16 mm thick – 3 mm ceramic ( 92% Alumina )and 3 mm rubber including CN Back – 300 x 300 – 17.5 mm square tile

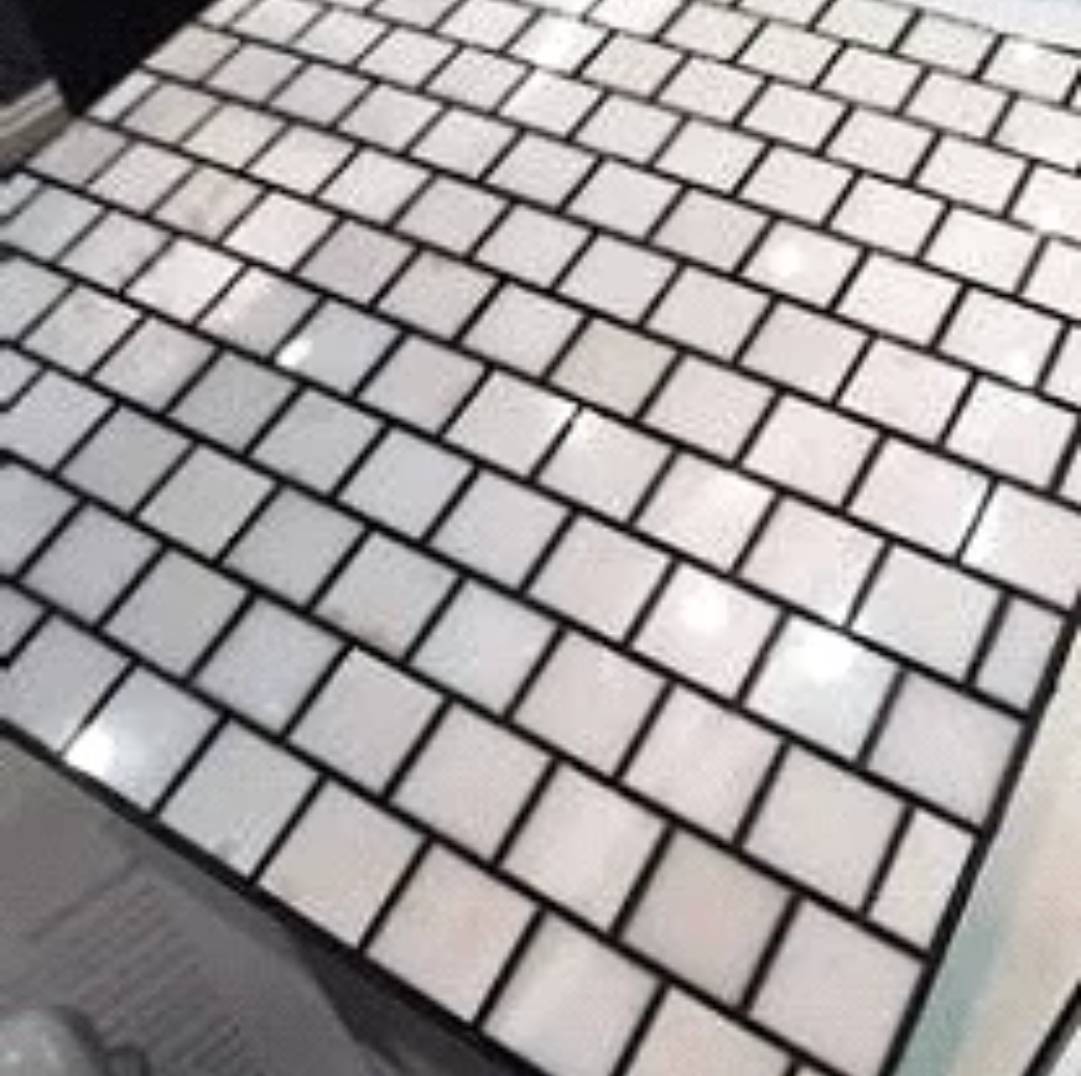

32 mm thick – 25 mm ceramic square tiles ( 92% Alumina )and 3 mm rubber including CN Back – 500 x 500 – 47.5 mm square tile

32 mm thick – 300 mm square impact liners with a single fixing anti-vibration screw that requires no hot work – in 92 % alumina and Zirconia Toughened Alumina – ( ZTA )

Our Standard wear plates available are

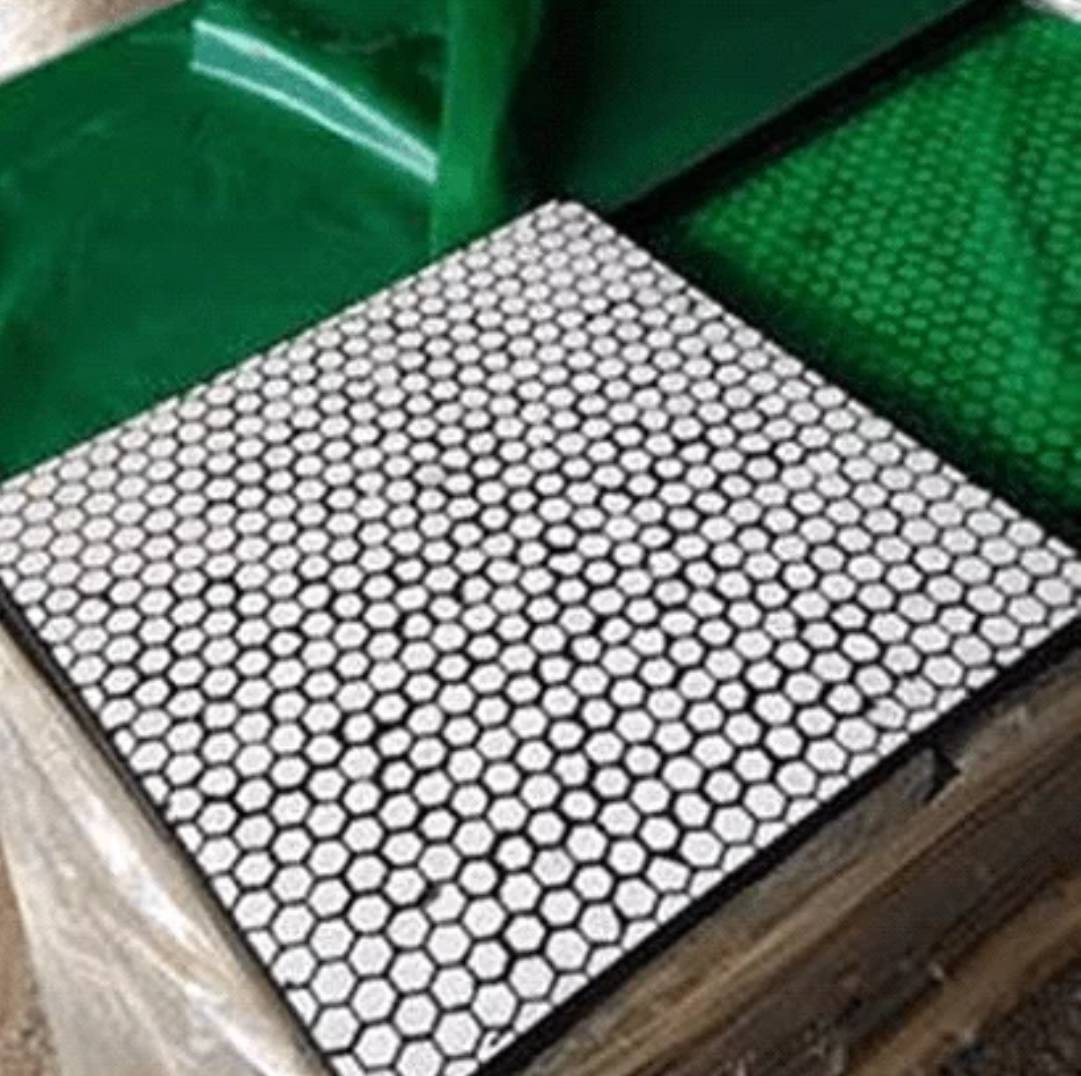

32 mm overall – ( 25 mm hex tile – 6 mm high abrasive and impact wear-resistant natural rubber ) – 500 x 500 with CN backing

20 mm overall – ( 14 mm hex tile – 6 mm high abrasive and impact wear-resistant natural rubber ) – 500 x 500 with CN backing

also available as

20 mm overall – ( 14 mm square tile – 6 mm high abrasive and impact wear-resistant natural rubber ) – 500 x 500 with CN backing

14 mm overall – ( 10 mm hex tile – 4 mm high abrasive and impact wear-resistant natural rubber ) – 500 x 500 with CN backing

10 mm overall – ( 5 mm hex tile – 5 mm high abrasive and impact wear-resistant natural rubber ) – 500 x 500 with CN backing

8 mm overall – ( 4 mm hex tile – 4 mm ) high abrasive and impact wear-resistant natural rubber ) – 500 x 500 with CN backing

6 mm overall – ( 3 mm hex tile – 3 mm ) high abrasive and impact wear-resistant natural rubber ) – 500 x 500 with CN backing

Ceramic wear plates are used to line chutes, hoppers, bunkers and in most places to substantially reduce ore build-up and increase the liner reliability with extended tonnes or millimeter handled

We custom manufacture liners where necessary to suit the application and specification as detailed by the end-user

If you require more information, please send us a message using the contact form below or by emailing sales@australianminingservices.com.au

We manufacture and supply sites around Australia