Ceramic Tiles and adhesives

- Home

- Products

- Wear Linings

- Ceramic Liners

- Ceramic Tiles and adhesives

Ceramic Tiles and Adhesives

Used mainly in applications of high abrasive wear, Australian Mining Product and Services offer a wide range of ceramic tile in various configurations and material to suit the applications such as transfer points, pipes, valves, hoppers that can wear excessively.

Materials ranging from Basalt, Alumina, Zirconia Toughened Alumina, Reaction bonded Silicon Carbide, partially stabilised Zirconia, the various forms can be sintered or ISO static press processes

Our Plain tiles or Direct bond tiles are usually 100 x 150 and in thicknesses of 6mm, 13mm, 25 mm and 50 mm

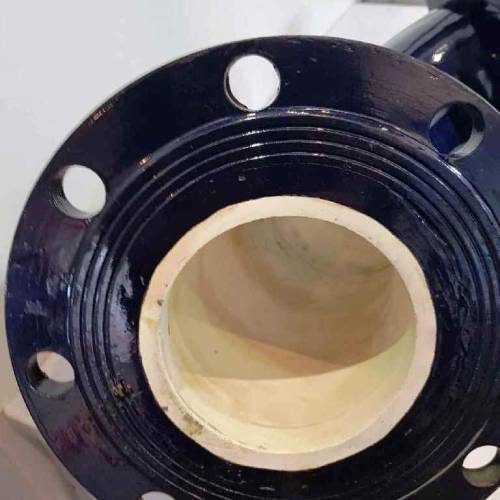

We offer fabricated pipe and pipe sections with ceramic lined internals using either a trapezoid pipe tile -or an iso static press cylinders – our trapezoid pipe liners can come in lengths of 150 to 300 to reduce the number of joints as well as to cut down on installation time

It is preferable that plant and equipment to be ceramic lined be first grit blasted to class 2 ½ to down to white metal and then coated with a suitable primer to prevent oxidization of the face to be lined, A suitable tile adhesive or an epoxy is then used to bond the liner to the substrate

All configurations of tiles as well as primers, and adhesives to suit are available

Durable Ceramic Tiles for Mining Applications

Key Benefits of Our Ceramic Tiles

- High Durability: Engineered to resist abrasion, impact, and corrosion, our ceramic tiles offer superior longevity even in the most demanding conditions.

- Thermal Stability: Capable of withstanding extreme temperatures, these tiles are perfect for use in areas exposed to high heat.

- Chemical Resistance: Our tiles are designed to resist chemical attacks, making them suitable for environments with exposure to aggressive substances.

- Easy Maintenance: Smooth surfaces allow for easy cleaning and maintenance, ensuring hygiene and operational efficiency.

- Versatility: Available in various sizes, shapes, and thicknesses, our tiles can be tailored to meet specific project requirements.

Best Practices for Installation

- Surface Preparation: Ensure the surface is clean, dry, and free from contaminants before applying adhesive.

- Correct Adhesive Choice: Match the adhesive properties with the specific needs of the mining environment.

- Proper Application: Follow manufacturer guidelines for adhesive application to ensure optimal bond strength.

- Curing Time: Allow sufficient curing time for adhesives to achieve full strength before subjecting the tiles to heavy loads or harsh conditions.

- Regular Inspection: Periodic inspections and maintenance can identify potential issues early, prolonging the life of the installation.

Advanced Adhesives for Reliable Installation

Key Features of Our Adhesives:

- Strong Bonding: Formulated to create a durable bond between tiles and substrates, preventing displacement and ensuring structural integrity.

- Fast Curing: Rapid curing times allow for quicker installation and reduced downtime, helping to keep projects on schedule.

- Flexibility: Our adhesives can accommodate slight movements and thermal expansion, preventing cracks and ensuring long-term performance.

- Resistance to Harsh Conditions: Designed to withstand extreme temperatures, moisture, and chemicals, our adhesives maintain their bonding strength in challenging environments.

- Ease of Application: User-friendly formulations allow for straightforward application, making the installation process efficient and reliable.

Why Choose Australian Mining Product and Services ?

We manufacture and supply sites around Australia