Remedial concrete repairs

Waterproofing, Remedial concrete repairs, industrial protective coatings against corrosion, abrasion, chemicals

Australian Mining Product and Services Pty Limited are a family-owned Australian, Brisbane-based business. We specialise and undertake most remedial and new applications for the protection of the substrate – be it, concrete or steel.

Our protection systems include the surface preparation of the application of a number of different protective coatings each selected to meet the requirement of the application

Applications :

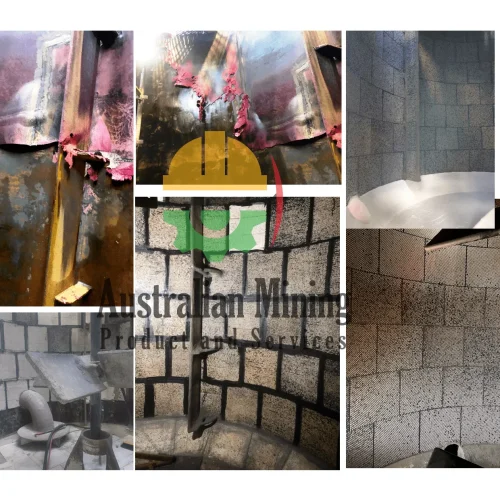

Tank Linings Residential / Commercial Waterproofing Rubber Linings

- Rubber lining Tanks

- Pre-cast Concrete Waterproofing

- HDPE Welding

- Structural Industrial Coatings

- Crack Injection

- Industrial Flooring

- Concrete Remediation

- Safety Line Marking

- Chemical and Hydrocarbon Bunding

- Containment Ponds

- Surface Preparation and Coating Removal

- Remedial Waterproofing

- Dustless coating Removal

- Water Blast clean

- Chemloc 205 application

- Linings to complement every – chemical – heat or reactive agent in most applications

- Tank Cleaning

- Polyurea spray on linings

- application of suitable sellers where required

- application of various approved suitable waterproofing membranes

We specialise in the supply of high-performance product formulations offering protection from corrosion, abrasion and chemicals.

Our main goal is to develop ongoing relations by maintaining a continued focus on improving our client’s assets and can offer services and support throughout the complete asset life cycle.

Our team of knowledgeable and trained staff has access to a large range of equipment and resources allowing us to work in tandem, around the clock across multiple sites.

Our industrial services partners are fully licensed with the Queensland Building and Construction Commission (QBCC) and all work is carried out in accordance with Australian Standard 3740-2010

Tank Lining and Waterproofing of Domestic Areas is our Speciality

Polyurea

1. What is Polyurea?

Polyurea is an elastomer substance derived from step-growth polymerization, which involves combining synthetic resin and isocyanate-reactive materials. Thus, the reaction of an isocyanate part with a resin blend component part through the step growth process of polymerization produces polyurea.

Various formulations of resins and isocyanates can provide the desired setting time, moisture resistance, pigmentation, flame retarding properties and other unique features.

There is no coating system that can successfully replace polyurea in all respects, due to its unique physical properties and durability.

However, its surface preparation requirements are very stringent.

Polyurea protects wooden, concrete and steel surfaces and structures from abrasion and corrosion damage.

It can help preserve a deteriorating concrete structure and help repair and keep canals intact. It resists scratches, chemicals, oils and salts in commercial and industrial floor applications. It can also preserve boats and other vessels by providing protection from cracking and deterioration.

Advantages of polyurea coatings include:

- Very fast setting (curing time typically 2 to 5 minutes) depending upon the formulation

- Excellent abrasion and scratch resistance

- Very stable resistance to weather and environmental conditions

- Very beneficial elongation characteristics

- Can be applied in variable temperature conditions, even in high humidity

- Stable heat resistance up to 130°C (266°F) and short-term rating of 220°C (430°F)

- Coating thickness can be finely controlled

- Very effective bonding on correctly prepared surfaces of wood, cement, concrete and metals

- Excellent chemical resistance

- Feasibility of low viscosity, thus enabling mixing and spraying at desired temperatures

- Can be formulated for a very high tensile strength upto 4350 psi

We manufacture and supply sites around Australia