Pipe Repair Bandage

- Home

- Pipe Repair Bandage

Repair Bandage

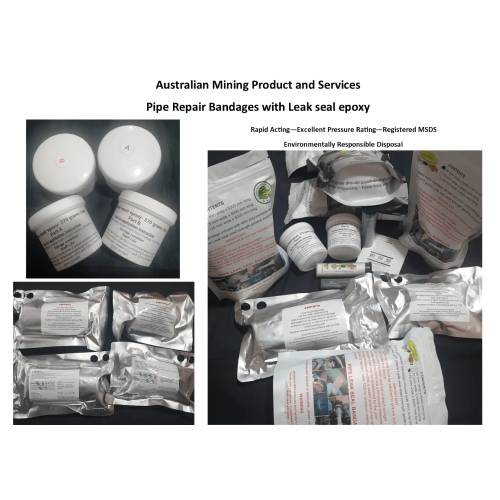

High-pressure, High-Strength Repair bandages many with free metal repair Epoxy are extensively used to arrest leaks that would otherwise cause an operation to schedule a voluntary stop or be forced to bring operations to a halt by the Environmental Protection Authority

The Resources industries – including Gas, Water, mineral processing, and extraction rely on the availability of such a product to minimise unscheduled stoppages Pipe Repair Bandages ( Polyurethane Impregnated Fiberglass) with Purpose Epoxy Leak Sealant.

Ex-stock -with instructions and Australian MSDS

Our active leak repair kits are designed to quickly stop any leakage from pipes even underwater

Instant Pipe repair bandages consist of E-glass fabric and are coated with water-activated polyurethane resin.

E-glass is more commonly used in the fiber-reinforced polymer composite industry manufactured from oxides of silicon, aluminum, calcium, magnesium, and boron.

These bandages demonstrate strength comparable to bandages currently available with improved resistance to chemicals, moisture, and heat.

Pipe Repair System for your pipe repair needs. Quick and simple to use with no mixing or measuring required.

A successful pipe repair can be achieved in only 30 minutes.

It uses environmentally friendly materials and is used for repairing oil, Gas, and water pipelines, etc, and adheres to Metal, plaster, PVC, Copper, Rubber, Fiberglass, Concrete, Wood, Ceramic, Polyester, etc.

It can be applied on cracked, fractured, corroded, damaged & leaking pipes, and can also be used around different shapes including straight lengths, tee, and elbow joints.

It is suitable for use on wet or dry pipes. It can even be applied underwater, in fresh or saltwater.

Our technical data sheet denotes how many multiple bandages you will require to achieve several wraps around a pipe to achieve pressure resistance. – email

sales@australianminingservices.com.au for the TDS.

Repair bandages ( Repair wrap or repair bandages)

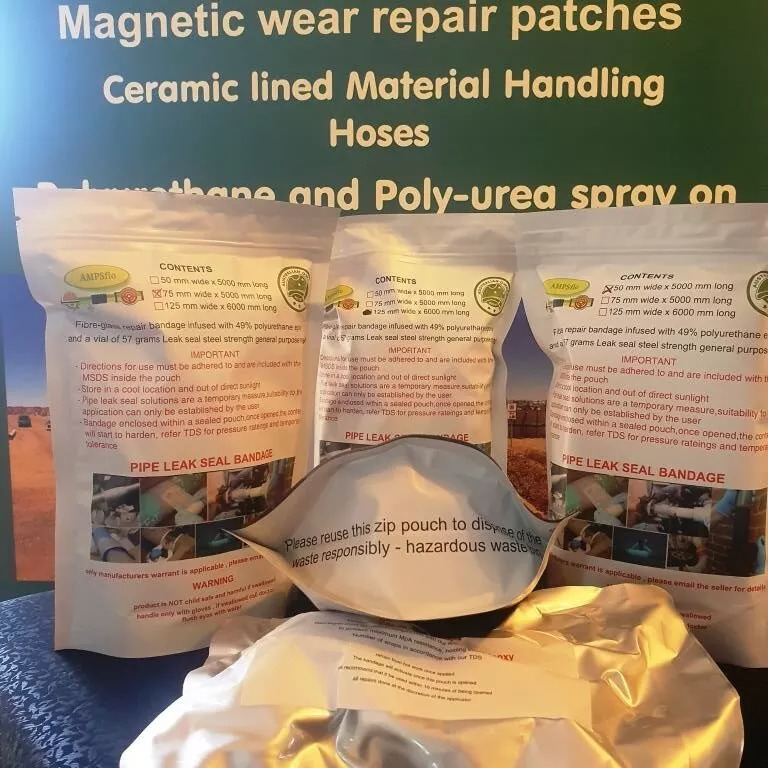

Our range offers 4 convenient sizes in the bandages each with our standard leak seal epoxy, with customers having the option to add our 570-gram pack of Instant leak seal Epoxy – as an additional purchase.

Every package contains an Australian-registered MSDS-( material safety Data sheet) as well as documented application (how-to-use) guidelines

Usually, pipe repair wraps are rated to 2500 KPA & tested to + 5000 plus KPA

Our range offers bandages that have been tested for resistance to pressure in most situations – WET OR DRY

Each high-strength, high-pressure repair bandage comes in a convenient to-handle width and length and includes a free 57-gram tube of our standard leak seal epoxy.

Customers have the option to add our 570 grams pack of Instant leak seal Epoxy – as an additional purchase

Our Technical Data Sheets advise the number of wraps you will require to achieve the desired pressure resistance

High-strength Pipe Repair Wrap is rated to 2500 KPA but ours has been tested to + 5000 plus KPA and this test can be viewed https://youtu.be/0H04oN6sxpw

- (high strength – high pressure )

- 50 mm wide (high strength – high pressure ) x 5000 long with one tube 57 gms pipe repair epoxy

- Pressure to a maximum of 2900p si – about 20000 Kpa (Min wrapping 15 layers, around the damaged area)

- 75 mm wide high strength – high pressure x 5000 long with one tube 57 gms pipe repair epoxy

- Pressure to a maximum of 2900 psi – about 20000 Kpa (Min wrapping 15 layers, around the damaged area)

- 125 mm wide x 6000 long with one tube 57 gms pipe repair epoxy

- Pressure to a maximum of 2900 psi – about 20000 Kpa (Min wrapping 15 layers, around the damaged area)

- Boxed set 125 x 6000 ( 2 bandages in box ) = 2 vials epoxy

- Instant repair 100 mm wide Nano strength for instant wrap without epoxy This 100 mm wide x 5000 with NO epoxy – it does not need epoxy – rated to 5 Mpa

- Underwater Epoxy with self-fusing Silicon tape

- Leak seal Kit

- Consists of two Underwater purposes sealing Epoxy – each 115 grams

- One roll of self-fusing silicon tape 100 mm wide x 5000 mm long

- Two instant repair bandages =- 100 mm wide x 5 meters long

6 Instant leak seal @ $ 21.00 per packet – excludes all applicable taxes and Freight (570 grams ) – working time under 120 seconds – fast cure – 600 seconds ) use by dates applicable

The Bandages are used to repair pipes with materials like copper, PVC plastic, steel, Cast iron, GRP, ceramic, concrete, lead, and most hoses from rubber or HDPE

Our polyurethane-impregnated fiberglass bandages comprise a knitted non-woven fiberglass structure, that gives the bandage maximum strength and facilitates repairs on corner joints, elbows, and other shaped fittings.

Amps-Flo pipe repair bandage is a fast-curing pipe repair bandage especially formulated to make quick and effective repairs of cracks, leaks, fractures, and corrosion porosity.

Advantages:

- Easy to use

- Can be applied underwater, in fresh and saltwater

- High strength

- High-pressure resistance

- Impact-resistant

- Can be sanded and painted as required

- Safe for use on potable water

- Specifically developed for industrial pipe repairs

- Two-year shelf life

- Permanent repair and extended service life of pipes

- Specification (Please contact us if you require MSDS & TDS)

- Resin Makeup: Water-activated polyurethane

- Heat Resistance: 150°C (300°F)

- Bonds to Most Pipes: Steel, Polypipe, PVC, Fibreglass, Copper

- Work-Life: 4 to 5 minutes, Tenacious bond after 5 to 10 minutes

- Functional Cure Time: Approximately 30 minutes

- Withstand pressure up to 400 psi (28 kg/cm2) * Pressure rating depends on the type of pipe and type of damage

What is a Repair Wrap?

When you need to seal a leak quickly in a transfer pipe, etc that is pressurised Repair wrap – our Repair bandage options are necessary

These Repair bandages while used on pipes can be used to leak arrest other plant and equipment to avoid unscheduled stoppages

Pipe Repair Wrap or repair bandage is a long-lasting but usually temporary simple-to-apply solution that is perfect for shielding mainly pipes against corrosion, abrasion, and impact in piping applications for mining, chemical handling, and petroleum refineries.

How To Use Pipe Repair Wrap?

Why Choose Australian Mining Products?

FAQs

We manufacture and supply sites around Australia