Gaskets, Seals., Packings

- Home

- Products

- Fluid Handling

- Gaskets, Seals., Packings

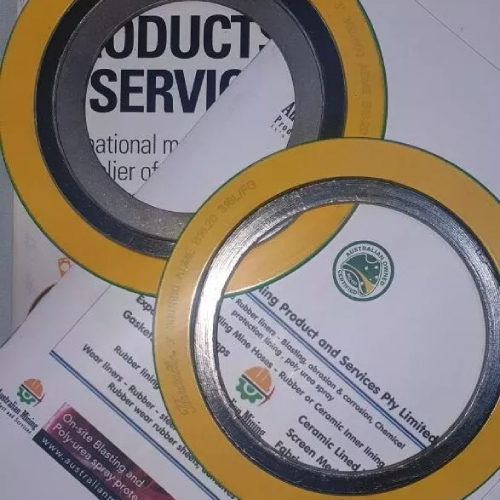

Gaskets, Seals., Packings

Gaskets, seals and packings are designed and intended to resist the flow of fluid from machinery face, head, joint and machinery gap or clearance.

Packing materials:

Rubbers – NR- NBR – Viton – Neoprene, butyl to suit the applications

Fibre, asbestos, cotton, synthetic materials, plastic, Teflon, graphite etc.

Gasket:

Gasketa area a mechanical seal that fill the space between two mating surfaces, generally to prevent leakage from or into the joined objects while under compression. G

Gaskets allow “less-than-perfect“ mating surfaces on machine parts where they can fill irregularities. Gaskets are commonly produced by cutting from sheet materials, such as gasket paper, rubber, silicone, metal, cork, felt, neoprene, nitrile rubber, fiberglass, or a plastic polymer (such as polychlorotrifluoroethylene)

Seals:

Seals are used to prevent the leakage of steam and lubricating oil.

Types of seals:

- Gland packing seal

- ‘O’ ring seal

- Oil ring seal

- Mechanical seal

- Oil film seal

- Dry gas seal

- Labyrinth seal

- Synthetic seal

Gland packing seal: It is used to prevent the leakage of gland steams in steam turbine.

‘O’ ring seal:

An O-ring, also known as a packing, or a toric joint, is a mechanical gasket in the shape of a torus. It is a loop of elastomer with a disc-shaped cross-section, designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface.

O-rings are one of the most common seals used in machine design because they are inexpensive, easy to make, reliable, and have simple mounting requirements. They can seal tens of megapascals (thousands of psi) pressure.

Oil ring seals:

Mechanical seals:

A mechanical seal is a device that helps join systems or mechanisms together by preventing leakage, containing pressure, or excluding contamination.

Mechanical seals offer

- Invisible leakage

- Less friction or power loss

- No to little wear on the shaft or sleeves

- Flexibility to accommodate shaft deflection and “End Play”.

- No Period Maintenance

- Long life

Labyrinth Seal:

Labyrinth seals on rotating shafts provide non-contact sealing action by controlling the passage of fluid through a variety of chambers by centrifugal motion, as well as by the formation of controlled fluid vortices. At higher speeds, centrifugal motion forces the liquid towards the outside and therefore away from any passages. Similarly, if the labyrinth chambers are correctly designed, any liquid that has escaped the main chamber becomes entrapped in a labyrinth chamber, where it is forced into a vortex-like motion. This acts to prevent its escape, and also acts to repel any other fluid. Because these labyrinth seals are non-contact, they do not wear out.

Synthetic seals

- Rubbers

- Nitriles

- Polyacrylates

- Silicones

Classification of seal services

- Light

- Moderate

- Heavy – duty

- Fluid separation

We manufacture and supply sites around Australia