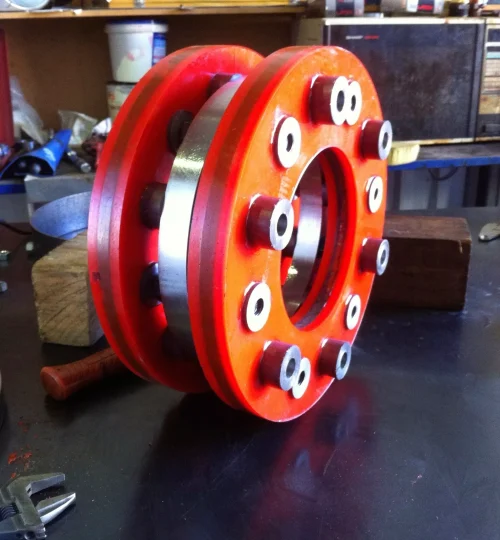

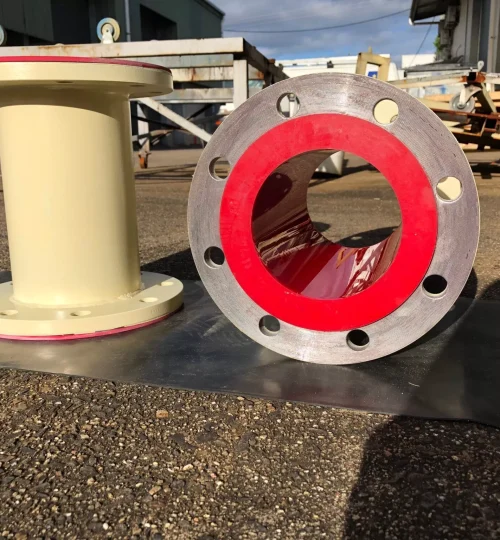

Polyurethane Elastomers are a range of extremely diverse materials and we engineer, by either spinning, spraying or casting enabling, Australian Mining Products and Service, to develop and produce a wide range of low quantity, high quality reliable products to suit every operational application in a diverse range of circumstances.

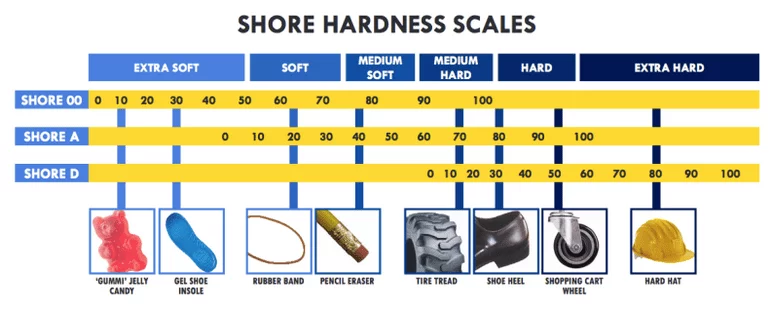

We offer, cold cast, Spray or trowel able grades and qualities that are specifically tailored for short turn-around specific site emergency repairs. We offer our autoclave cured hot cast polyurethane or spray material to meet exactly site operational criteria as well as optimum site performance. Our techniques as well as our wide range of start out chemicals can deliver products that achieve specific hardness’s required as well as physical properties, to meet the requirement of the operational parameters.